Lightweight Insulating Concrete

Roof Deck Systems

What are lightweight insulating concrete roof decks?

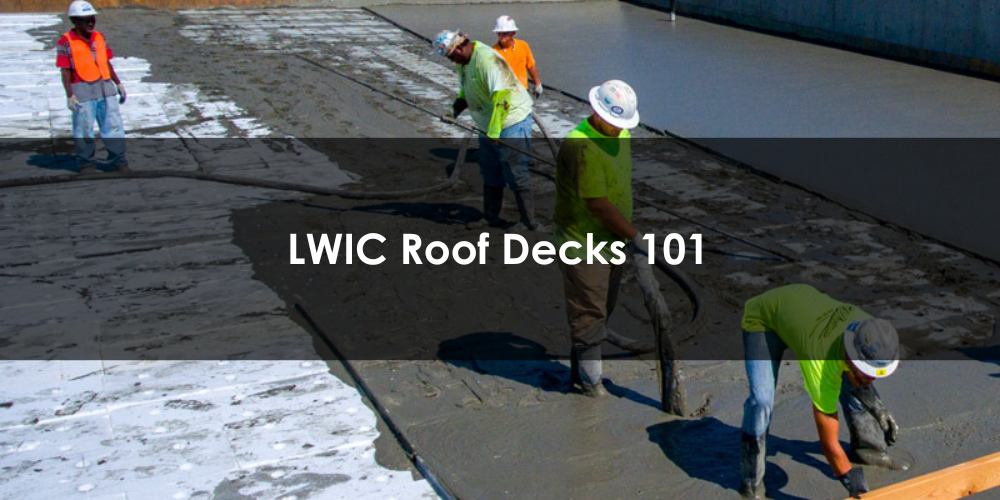

Lightweight insulating concrete (LWIC) roof decks are high-performance roof insulation systems that reduce roof maintenance and replacement costs. LWIC is a mixture of Portland cement, water, and preformed foam. The foam creates a structure of discrete air cells within the material, which makes it highly flowable, with low density and light weight.

We batch LWIC onsite and pour a slurry layer over the roof substrate. Then, we lay EPS “holey board” insulation custom-cut to the desired thickness and slope. Finally, we pour a top-coat of LWIC over the insulation, on top of which a roofing membrane can be installed.

LWIC roof decks are an excellent choice in many roofing applications, as they provide high R-values, increased fire and wind ratings, and decrease the life cycle cost of the roof compared to traditional roof deck systems.

Advantages of LWIC roof decks

LWIC roof decks offer many benefits over traditional ISO board systems, including:

- LWIC eliminates the need to tear off the existing roof during reroofing, since it can be poured directly over the previous membrane. This reduces the mess and expense of tearing off old insulation, minimizes debris, and causes less negative impact on the environment.

- Since traditional tapered insulation systems involve multiple layers of board to create a sloped system, they require more time, money, and labor. LWIC systems typically save $2-4 per square foot, when compared to tapered polyiso roof systems.

- LWIC roof decks have built-in fireproofing capabilities, saving owners and roofers money and mitigating the need to install additional fireproofing.

- LWIC roofs can save building owners reroofing costs, since they are less likely to be destroyed in high-wind environments.

- It is more efficient to lay a single EPS holey board rather than layer multiple ISO boards over one another (especially as those boards have to be nailed or drilled into the roofing substrate).

- LWIC roof decks save time in reroofing projects because they can be installed directly over the existing roofing in most situations.

With traditional reroofing projects, the roofing contractors must entirely tear away the old roof and dispose of it in a landfill. LWIC roof decks can be installed directly over the existing roof.

LWIC roof decks have no joints and are dimensionally stable, creating a monolithic surface that reduces stress. LWIC also slows the heating and the cooling of the membrane, reducing thermal stress compared to traditional insulation systems and increasing the overall life span of the roof.

LWIC roof systems provide a stable R-value, unlike traditional ISO boards, which lose about 4% of their R-value every year. Over time, LWIC roof decks provide significantly better insulation performance than traditional roof deck systems.

Want to learn more?

Read our LWIC roof deck buyer’s guide to learn more about our mix design, how we pour and install roof decks, and specific benefits that would be helpful to know before buying.

Why choose Nettles as your LWIC roof deck contractor?

Nettles Construction Solutions has over 75 years of experience with LWIC and roof deck systems. We are experts in mix designs, as well as pumping the material correctly and precisely. We’ve installed LWIC roof decks in dozens of states, spanning a wide array of building types, roofing substrates, weather conditions, and other contexts–meaning that we’ll be able to tailor our processes to your specific project to ensure that it’s completed on time, under budget, and with the highest-quality service.

LWIC roof deck FAQs

Yes, we provide all materials except for the water and water meter, including the cement and foaming agent.

A typical LWIC roof deck has a compressive strength of 200-250 psi, compared to 5,000 for structural foundational concrete, and 2,500-3,500 for lightweight concrete (which is often used in floors and balconies). LWIC roof decks are only 4-5 lbs per square foot heavier than traditional ISO board roof deck systems.

We can pump and pour LWIC up to 40 stories high.

We don’t pour when it’s below freezing, but we can pour LWIC in up to 110 degree heat.

A variety of variables can influence the price of your roof deck, including the size, height, and slope of the roof, as well as the distance to the jobsite.

LWIC is cured 48-72 hours after the pour, at which point the roofing membrane can be installed on top of it.

We install LWIC roof decks throughout the midwest, from the Gulf of Mexico up through the Dakotas.

Talk to a roof deck expert

Kevin Soots

832.472.4021

kevin.soots@nettlescs.com

Dan Hissong

913.579.9003

dan.hissong@nettlescs.com

Bryan Batchman

979.451.8600

bryan.batchman@nettlescs.com

Mark Van Doren

816.797.8097

mark.vandoren@nettlescs.com

Have questions?

"*" indicates required fields